Page 22 - 20190101 part 6 (EN)

P. 22

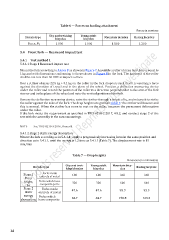

Table 6 — Forces on loading attachment

Forces in newtons

City and trekking Young adult

Bicycle type bicycles bicycles Mountain bicycles Racing bicycles

Force, F5 1 000 1 000 1 500 1 200

5.4 Front fork — Rearward impact test

5.4.1 Test method 1

5.4.1.1 Stage 1 Rearward impact test

Mount the fork according to Annex B as shown in Figure 7. Assemble a roller of mass less than or equal to

1 kg and with dimensions conforming to those shown in Figure 8 in the fork. The hardness of the roller

shall be not less than 60 HRC at impact surface.

Rest a striker of mass 22,5 kg ± 0,1 kg on the roller in the fork dropouts such that it is exerting a force

against the direction of travel and in the plane of the wheel. Position a deflection measuring device

under the roller and record the position of the roller in a direction perpendicular to the axis of the fork

steerer and in the plane of the wheel and note the vertical position of the fork.

Remove the deflection measuring device, raise the striker through a height of h 4, and release it to strike

the roller against the rake of the fork. The drop heights are given in Ta ble 7. The striker will bounce and

this is normal. When the striker has come to rest on the roller, measure the permanent deformation

under the roller.

If the fork meets the requirement as specified in TBIS 4210-2:2017, 4.9.2, and conduct stage 2 of the

test with the assembly in the same mountings.

NOTE See TBIS 4210-3:2016, Annex B.

5.4.1.2 Stage 2 Static energy absorption

Mount the fork according as in 5.4.1.1, apply a progressively increasing force in the same position and

direction as in 5.4.1.1, until the energy is 1.2 time as 5.4.1.1(Table 7). The displacement rate is 15

mm/min

Table 7 — Drop heights

Dimensions in millimetres

City and trek- Young adult Mountain bicy-

Bicycle type Racing bicycles

king bicycles bicycles cles

Stage 1 Forks made 180 180 360 360

Drop entirely of metal

height, Forks which have 320 320 600 640

h4 composite parts

Stage 2 Forks made

Static entirely of metal 47.6 47.6 95.3 95.3

energy Forks which

absorption, have composite 84.7 84.7 158.8 169.3

J parts

14