Page 20 - 20190101 part 6 (EN)

P. 20

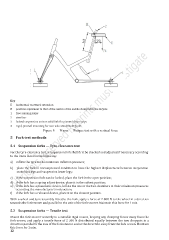

Key

E horizontal, rearward extension

H position equivalent to that of the centre of the saddle clamp with the bicycle

1 free-running roller

2 steel bar

3 locked suspension unit or solid link for pivoted chain stays

4 rigid, pivoted mounting for rear axle attachment point

Figure 5 — Frame — Fatigue test with a vertical force

5 Fork test methods

5.1 Suspension forks — Tyre-clearance test

For the tyre-clearance test, a suspension fork shall first be checked and adjusted if necessary according

to the items listed in the following:

a) inflate the tyre to the maximum inflation pressure;

b) place the fork in uncompressed condition to have the highest displacement between suspension

stanchion legs and suspension lower legs;

c) if the suspension fork can be locked, place the fork in the open position;

d) if the fork has a spring adjust device, place it in the softest position;

e) if the fork has a pneumatic device, inflate the one or the two chambers at their minimum pressures

according the manufacturer’s instruction;

f) if the fork has a rebound device, place it on the slowest position.

With a wheel and tyre assembly fitted to the fork, apply a force of 2 800 N to the wheel in a direction

towards the fork-crown and parallel to the axis of the fork steerer. Maintain this force for 1 min.

5.2 Suspension forks — Tensile test

Mount the fork steerer securely in a suitable rigid mount, keeping any clamping forces away from the

fork-crown, and apply a tensile force of 2 300 N distributed equally between the two dropouts in a

direction parallel to the axis of the fork steerer and in the direction away from the fork crown. Maintain

this force for 1 min.

12