Page 29 - TBIS_79010-2019_(EN)_1nd

P. 29

TBIS 79010:2019

4.3. Frame and front fork assembly

4.3.1 Suspension-frames – Special requirements

The design shall be such that if the spring or damper fails, neither the tyre shall

contact any part of the frame nor the assembly carrying the rear wheel become

detached from the rest of the frame.

4.3.2 Frame – Impact test (falling mass)

4.3.2.1 Requirements

When tested by the method described in 4.3.2.2, there shall be no visible cracks or

fractures of the frame. The permanent deformation measured between the axes of

the wheel axles shall not exceed the following values:

a) 30 mm where a fork is fitted;

b) where a dummy fork is fitted in place of a fork, the values are given in Table 3.

NOTE See Annex B (normative) Dummy fork characteristics.

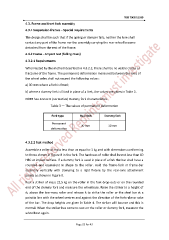

Table 3 — The values of permanent deformation

Fork type Real fork Dummy fork

Permanent

30 mm 10 mm

deformation

4.3.2.2 Test method

Assemble a roller of mass less than or equal to 1 kg and with dimensions conforming

to those shown in Figure 8 in the fork. The hardness of roller shall be not less than 60

HRC at impact surface. If a dummy fork is used in place of a fork the bar shall have a

rounded end equivalent in shape to the roller. Hold the frame-fork or frame-bar

assembly vertically with clamping to a rigid fixture by the rear-axle attachment

points as shown in Figure 8.

Rest a striker of mass 22,5 kg on the roller in the fork drop-outs or on the rounded

end of the dummy fork and measure the wheelbase. Raise the striker to a height of

h 1 above the low-mass roller and release it to strike the roller or the steel bar at a

point in line with the wheel centres and against the direction of the fork rake or rake

of the bar. The drop heights are given in Table 4. The striker will bounce and this is

normal. When the striker has come to rest on the roller or dummy fork, measure the

wheelbase again.

Page 25 for 43