Page 85 - TBIS_15194-2019_(EN)_3nd

P. 85

TBIS 15194:2019

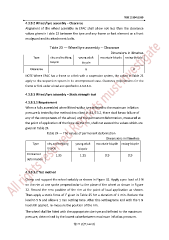

4.3.9.2 Wheel/tyre assembly – Clearance

Alignment of the wheel assembly in EPAC shall allow not less than the clearance

values given in Table 23 between the tyre and any frame or fork element or a front

mudguard and its attachment bolts.

Table 23 — Wheel/tyre assembly – Clearance

Dimensions in illimetres

Type city and trekking young adult mountain-bicycle racing-bicycle

bicycle bicycle

Clearance 6 4

NOTE Where EPAC has a frame or a fork with a suspension system, the values in Table 23

apply to the suspension system in its uncompressed state. Clearance requirements for the

frame or fork under a load are specified in 4.3.8.3.1.

4.3.9.3 Wheel/tyre assembly – Static strength test

4.3.9.3.1 Requirement

When a fully assembled wheel fitted with a tyre inflated to the maximum inflation

pressure is tested by the method described in 4.3.9.3.2, there shall be no failure of

any of the components of the wheel, and the permanent deformation, measured at

the point of application of the force on the rim, shall not exceed the values which are

given in Table 24.

Table 24 — The values of permanent deformation

Dimensions in illimetres

Type city and trekking young adult mountain-bicycle racing-bicycle

bicycle bicycle

Permanent 1.35 1.35 0.9 0.9

deformation

4.3.9.3.2 Test method

Clamp and support the wheel suitably as shown in Figure 32. Apply a pre-load of 5 N

on the rim at one spoke perpendicular to the plane of the wheel as shown in Figure

32. Record the zero position of the rim at the point of load application as shown.

Then apply a static force of F given in Table 25 for a duration of 1 min. Reduce the

load to 5 N and allow a 1 min settling time. After this settling time and with the 5 N

load still applied, re-measure the position of the rim.

The wheel shall be fitted with the appropriate size tyre and inflated to the maximum

pressure, determined by the lowest value between maximum inflation pressures

第 77 頁共 162 頁