Page 74 - TBIS_15194-2019_(EN)_3nd

P. 74

TBIS 15194:2019

axis of the wheel-axle or simulated axle in relation to the axis of the fork steerer,

shall not exceed 45 mm. After which, it shall exhibit no fractures, then it shall be

subjected to a second test as described in 4.3.8.5.4 c) Torque on fork, irrespective of

the amount of permanent deformation, there shall be no relative movement

between the steerer and the crown.

4.3.8.5.3 Test method 1

Mount the fork according to Annex G as shown in Figure 25. Assemble a roller of

mass less than or equal to 1 kg and with dimensions conforming to those shown in

Figure 26 in the fork. The hardness of the roller shall be not less than 60 HRC at

impact surface.

Rest a striker of mass 22,5 kg ± 0,1 kg on the roller in the fork drop-outs such that it

is exerting a force against the direction of travel and in the plane of the wheel.

Position a deflection measuring device under the roller and record the position of

the roller in a direction perpendicular to the axis of the fork steerer and in the plane

of the wheel and note the vertical position of the fork.

Remove the deflection measuring device, raise the striker through a height of h4 and

release it to strike the roller against the rake of the fork. The drop heights are given

in Table 18. The striker will bounce and this is normal. When the striker has come to

rest on the roller, measure the permanent deformation under the roller.

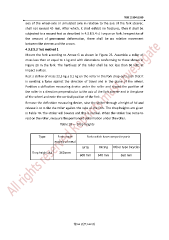

Table 18 — Drop heights

Type Forks made Forks which have composite parts

entirely of metal

MTB Racing Other type bicycles

Drop height, h4 360 mm

600 mm 640 mm 360 mm

第 66 頁共 162 頁