Page 37 - 20190101 part 6 (EN)

P. 37

TBIS 4210-6:2019

Annex E

(informative)

Stiffness measurement of frame

E1: General

1. The test method of the item is applicable to the frames defined by TBIS 4210.

2. It is necessary to use a new frame/front fork set, and completely assembling process by the

default head set. If only the frame is provided, it is allowed to replace the original front fork

by the simulated front fork with the same length (as described in Annex A of TBIS 4210-

6:2017); however, it stiffness should not be lower than the original front fork.

3. If the sample to be executed is a shock frame, it is necessary to use the stiffness connection

bar to replace the shock component; please note that the gap between the fixation points of

two ends of the connection bar and the strength of the lateral stiffness in order to simulate

the original configuration of the frame.

4. The force should be slowly increased to reach the setting in order to avoid that the shock

influences the deformation of the frame.

5. Before the force is applied, it is necessary to use 20% of the setting value of the force as the

preload, and keep applying the force for 1 minute; after the preload is executed for several

times, please release the preload, and reset the displacement; then, please use 100% of the

force to execute the test.

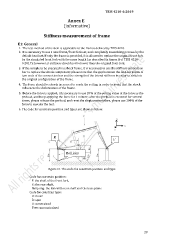

6. The code for constrain position and types are show as below:

R

F

Ball joint

Figure E1 The code for constrain position and type.

Code for constrain position:

F: the shaft of the front fork,

R: the rear shaft,

Ball joing: the link with rear shaft and the base plane

Code for constrain type:

U: move

R: spin

0: constrained

Free: unconstrained

29